Emerging Trends in High-Temperature Superconducting Magnet Technology and Its Applications

- Seungyong Hahn, Professor, Department of Electrical and Computer Engineering, Seoul National University

- JuKyung Cha, Ph.D. Candidate, Department of Electrical and Computer Engineering, Seoul National University

- Dongsu Seo, Master's Student, Department of Electrical and Computer Engineering, Seoul National University

- Jung Tae Lee, Postdoctoral Researcher, Applied Superconductivity Center, Seoul National University

Seungyong Hahn

1. What is Superconducting Technology?

1-1. Definition and Discovery of Superconductivity

Superconductivity is a phenomenon in which certain materials exhibit zero electrical resistance below a critical temperature. In the superconducting state, electric current flows without energy loss, enabling efficient high-power transmission and the generation of strong magnetic fields, which in turn allows for the miniaturization of magnets. The phenomenon was first observed in 1911 by Heike Kamerlingh Onnes, who discovered that mercury lost all electrical resistance when cooled in liquid helium (at a temperature of 4.2K).

1-2. A Century of Superconducting Technology Development

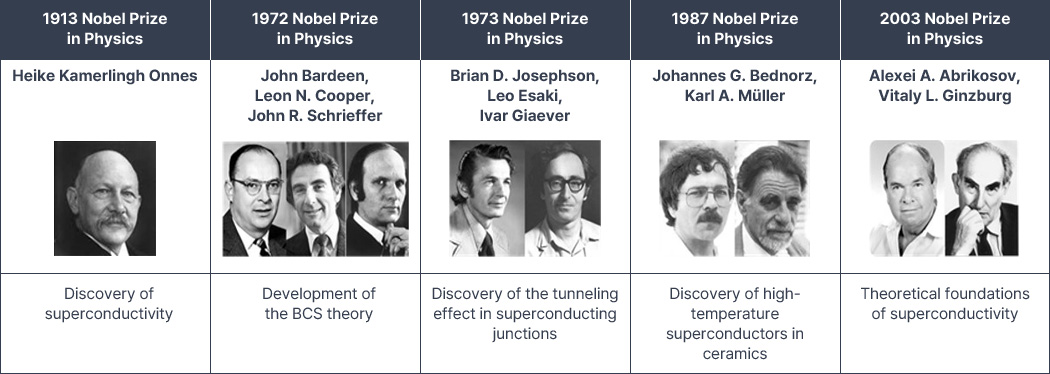

Since its discovery by Heike Kamerlingh Onnes, superconductivity has been the subject of extensive research, resulting in five Nobel Prizes in Physics over the past century (Figure 1). Notably, in 1986, Bednorz and Müller discovered high-temperature superconductors (HTS), setting a record for the shortest time-just 18 months-between discovery and Nobel recognition. Their groundbreaking work led to the identification of many superconducting materials with critical temperatures exceeding 30K, including YBCO, which has a critical temperature of 95K. In recent years, there has been growing global interest in room-temperature superconductors.

1-3. High-Temperature Superconductors and the No-Insulation Winding Technique

Traditional low-temperature superconductors (LTS) are typically made from alloys and require cooling with expensive liquid helium (approximately 50,000 KRW per liter) to maintain temperatures around 4K. In contrast, HTS materials, such as the (RE)BCO (where RE stands for rare earth elements), have critical temperatures above 77K. This allows for cooling with liquid nitrogen, which costs roughly as 1/50 as much as liquid helium. However, HTS magnets are vulnerable to quench events-sudden losses of superconductivity that can result in rapid overheating and severe electrical damage within seconds. While these quenches can be caused by material inhomogeneities, design flaws, or even operational error, they pose a critical challenge for the commercialization of HTS technology. As a result, HTS magents have often suffered damage from such rapid overheating, and since protecting the coils under these conditions is virtually impossible, quench events have long been considered‘uncontrollable accidents.'This has made them one of the most significant technical hurdles limiting the practical application of HTS magnets to this day.

2011 Emergence of No-insulation High-Temperature Superconducting (HTS) Technology and a Paradigm Shift in HTS Magnet Protection Techniques

In 2009, the author first introduced the No-Insulation (NI) High-Temperature Superconductor (HTS) Winding Technique at the MIT Francis Bitter Magnet Laboratory. This technique intentionally eliminates turn-to-turn insulation in conventional superconducting coil winding. As a result, when a quench occurs, the fault current can automatically bypass the quenched region through adjacent turns, effectively preventing thermal runaway and significantly improving the operational stability of HTS magnets (Figure 2).1)

This approach has since been recognized as a breakthrough that challenges the long-held notion in the HTS field that"a quench equals failure."It introduced a new paradigm for HTS magnet protection and has spurred global research efforts aimed at realizing an "electrically non-destructive" HTS magnet.

2012-2018 Demonstration of the Potential of No-insulation HTS Technology

In the early 2010s, as various early-stage studies on no-insulation (NI) high-temperature superconducting (HTS) magnets were being conducted worldwide, Korean researchers at SuNAM developed a 26T NI HTS magnet, nearly quadrupling the previous wolrd record of 7T held by MIT. This achievement was recognized as the most cited paper of 2016 by the *Superconductor Science and Technology*, published by the Institute of Physics (IOP). It was followed by a series of notable milestones, including the development of a 400MHz NI HTS NMR system by the Korea Basic Science Institute, the commercial sale of an 18T Axion Detection magnet by SuNAM, and the successful development of a 20T fusion magnet by MIT's Commonwealth Fusion Systems. In 2017, NI HTS coil technology was officially included in IEEE's technical standards. Furthermore, CERN has been actively pursuing the use of NI HTS magnets for the upgrade of the Large Hadron Collider. This direction was highlighted at the 2019 WAMHTS workshop focusing on "No-Insulation" technologies.

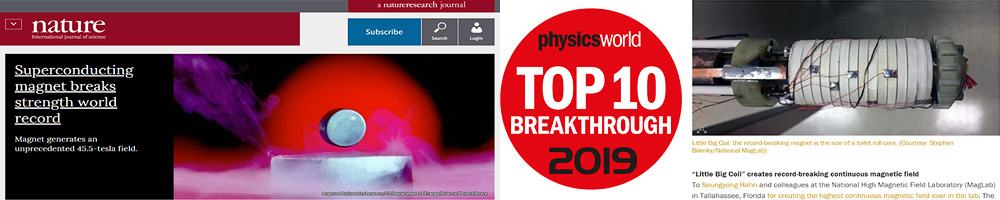

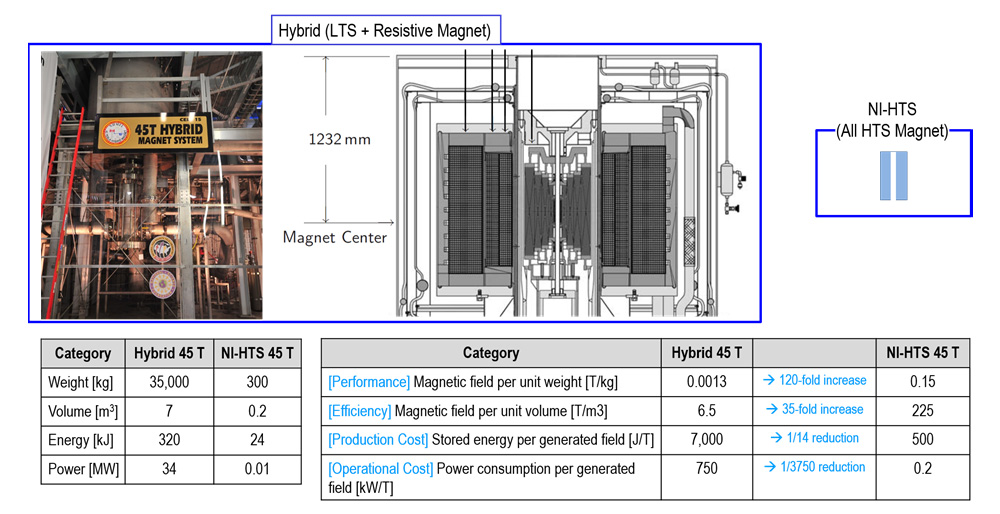

2019 Achievement of a World Record in DC Magnetic Field

In June 2019, the Applied Superconductivity Laboratory at Seoul National University, in collaboration with the U.S. National High Magnetic Field Laboratory, set a world record by generating a 45.5T DC magnetic field using NI HTS magnet technology. This accomplishment was published in *Nature* (Figure 3) and selected as one of Physics World's "Top 10 Breakthroughs for 2019." As shown in Figure 4, when compared to the previously record-holding 45T hybrid magnet developed by the U.S. National High Magnetic Field Laboratory, the NI HTS magnet demonstrates remarkable improvements in performance, usability, and cost-effectiveness, sparking increased interest in the commercialization of NI HTS technology in Korea.

Post-2020 Era of Global Competition

The advent of NI HTS technology has expanded the potential applications of HTS magnets, leading to intensified global competition in their development and commercialization. Currently, most major international conferences on superconductivity feature dedicated sessions on NI technology. A wide range of industries-including healthcare, materials science, energy, environment, advanced science, and electric propulsion-are increasingly engaging in the development of HTS magnets. In Korea, recognizing the strategic importance of NI HTS technology, the Ministry of Science and ICT established the HTS Magnet Core Technology Project in 2022. The project is actively pursuing foundational research on developing ultra-high-field magnets based on NI HTS technology with the goal of future commercialization.

2. Major Application Areas of High-Temperature Superconducting (HTS) Technology

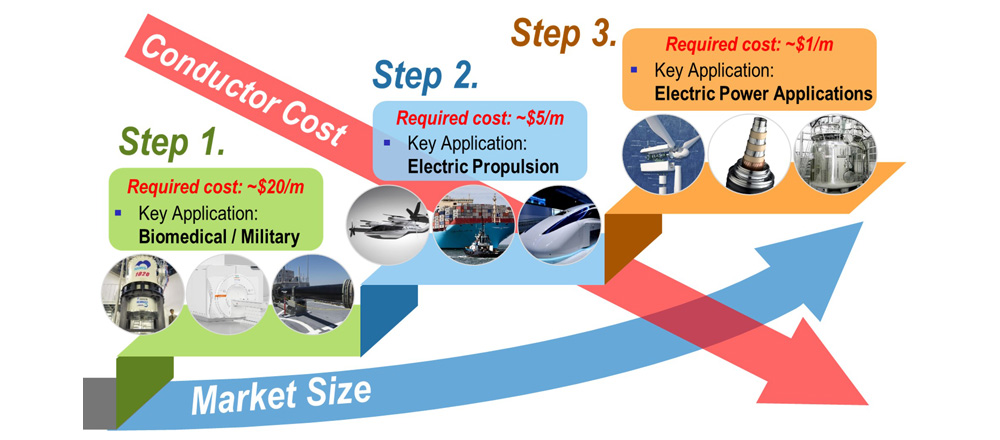

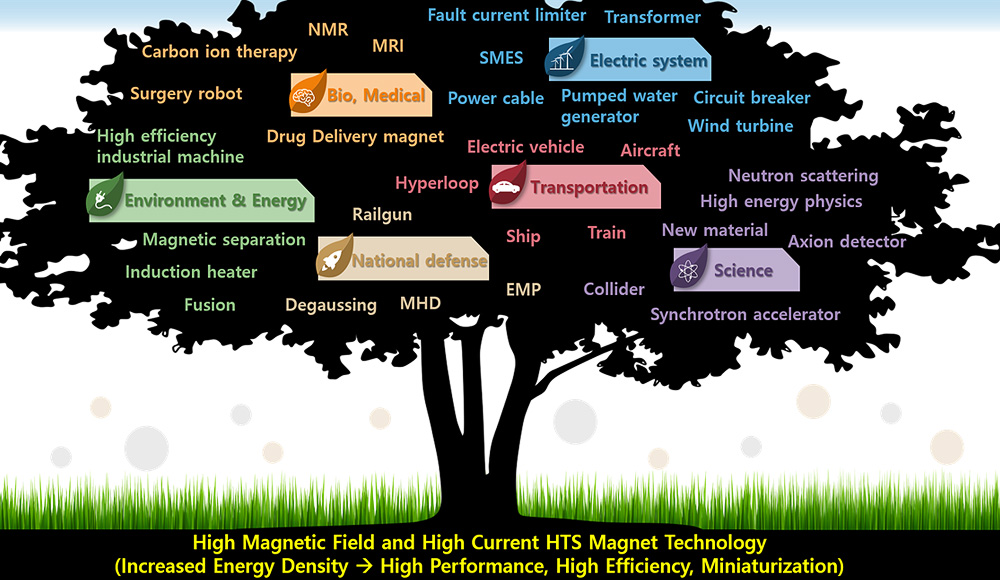

The PRISM Research Group (Pioneering Research Initiative for Superconducting Magnets) is promoting a three-phase industrialization strategy for HTS applications categorized by short-, mid-, and long-term goals (Figure 5). This roadmap reflects the anticipated reduction in HTS wire costs as mass production scales up, and categorizes target applications based on projected market competitiveness: (1) short-term: defense and medical/bio; (2) mid-term: electric propulsion; and (3) long-term: power systems. While Chapter 4 provides a detailed discussion of defense applications, this section briefly introduces non-defense areas. Notably, as summarized in Figure 6, HTS magnet technology is also regarded as a core enabling technology with broad manufacturing applications beyond the three primary sectors outlined in the industrialization strategy.

2-1. [Short-term] Medical: MRI Systems and Therapeutic Particle Accelerators / Bio: NMR for Drug Development

HTS applications that are already economically competitive at current conductor prices are primarily found in the medical and bio sectors. In the medical field, MRI (Magnetic Resonance Imaging) is a representative example widely used for disease diagnostics. While 3T MRI systems based on LTS are currently the standard, ongoing research is aiming to increase magnetic field strength up to 14T using HTS technology to achieve higher resolution imaging. Moreover, HTS magnets are being explored to miniaturize therapeutic particle accelerators-such as those used in carbon ion therapy-from 10m to 1m. In the bio sector, NMR (Nuclear Magnetic Resonance) systems for protein analysis in drug development play a vital role. Commercialization of GHz-level (23T and above) HTS NMR systems is now actively underway, surpassing the current LTS limit of 900 MHz (21T).

2-2. [Mid-term] Electric Propulsion: UAM, Hyperloop, Eco-Friendly Transport

The mid-term application area centers on electric propulsion systems that leverage the powerful magnetic fields generated by high-temperature superconducting (HTS) magnets. These systems aim to achieve lightweight, compact, high-efficiency, and high-power performance in various modes of transportation. In particular, electric propulsion is gaining attention as a core technology for realizing carbon neutrality in the logistics sector, both domestically and internationally, as it can replace conventional vehicles-such as buses, trucks, and ships-without emitting exhaust gases, even amid rising transportation demand.

A representative example is Urban Air Mobility (UAM), often referred to as "flying cars", which offers a potential solution to urban traffic congestion while maximizing mobility efficiency. Major global leading companies including Hyundai Motor Company (Korea), Airbus (France), and Toshiba (Japan) are actively developing UAM systems, with the goal of significantly reducing the weight and improving the efficiency of propulsion units through HTS motor technology.

Another notable case is the Hyperloop-an ultra-high-speed transportation system expected to reach speeds of approximately 1,000 km/h, potentially reducing travel time between Seoul and Busan to approximately one hour. In Korea, a preliminary feasibility study is currently underway for this project, which is expected to incorporate a levitation system based on no-insulation HTS magnets. A prototype of this system has already been developed by the Korea Railroad Research Institute.

2-3. [Long-term] Power and Energy: Fusion, Large-Scale Power Devices

The long-term area targets the power and energy sector, which represents the largest potential market within the three-phase industrialization strategy. Amid the surge in global electricity demand-fueled by the rapid expansion of data centers, artificial intelligence (AI), and electric propulsion systems-expectations for nuclear fusion as a clean energy source at an all-time high. In response, over the past several years, leading big tech and AI companies have collectively invested more than 10 trillion KRW into nuclear fusion to secure the vast energy needed for data processing and AI computation.

Korea has also achieved a world first commercialization of superconducting power cables, which enable the efficient transmission of large-scale electricity. A 1-kilometer segment of high-temperature superconducting (HTS) cable is currently in long-term commercial operation between Heungdeok and Singal, and a new extension between Yeokgok and Onsu is underway.

Furthermore, KEPCO, in collaboration with LS Cable & System, is conducting the world's first demonstration project for a superconducting platform that connects suburban substations with urban superconducting stations using HTS cables.

In addition, HTS-based Superconducting Magnetic Energy Storage (SMES) devices are being considered as complementary alternatives to conventional battery-based Energy Storage Systems (ESS). SMES devices offer key advantages-such as fire safety, virtually unlimited lifespan, and high power output-making them well-suited to overcome the fire risk and limited lifespan associated with conventional battery technologies.

2-4. [Long-term] HTS Wire Price Decline Trends Driven by Fusion and Emerging Industrial Demands

Experts generally agree that achieving economically viability in the mid- and long-term sectors will require a reduction in the cost of high-temperature superconducting (HTS) wire. Recently, however, soaring demand from the compact nuclear fusion sector has fueled rapid growth in the HTS wire market. In response, leading countries have begun investing in large-scale HTS wire production facilities.

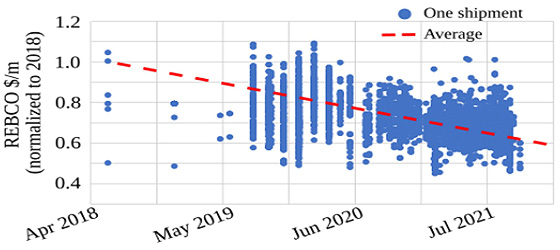

As a result, the price of HTS wire-which had remained virtually unchanged for over 40 years-has dropped by nearly 40% in just the past few years (see Figure 7). While some view that this may be a temporary effect driven by a short-term lived boom in the fusion sector, others interpret it as a signal of the broader commercialization breakthrough of HTS technology. Either way, this shift is opening up promising opportunities for companies worldwide-including those in Korea-that are developing HTS-based applications, as the technology moves closer to mainstream industrial adoption.

3. Establishing a National Flagship Brand in Superconducting Technology: HTS Magnet Core Technology Research Group

3-1. Structure and Philosophy of the High-Temperature Superconducting Magnet Core Technology Research Group (PRISM)

Launched in 2022, the PRISM research group operates under the motto "One Nation, One Lab, One University." Backed by a five-year budget of KRW 46.4 billion, the initiative brings together 27 institutions from industry, academia, and research, with participation from more than 220 researchers.

PRISM ultimately aims to foster high-temperature superconducting (HTS) magnet technology into a new national flagship brand for South Korea. The group is guided by two core principles: the world's first commercialization and the luxury-grade refinement of HTS technology.

Worldwide, the HTS magnet market remains in its infancy, and no single nation yet holds a dominant position in the core technologies. Given the transformative potential of HTS magnets across diverse industrial sections, PRISM seeks to secure a first mover advantage by pioneering and securing ownership of fundamental HTS magnet technologies.

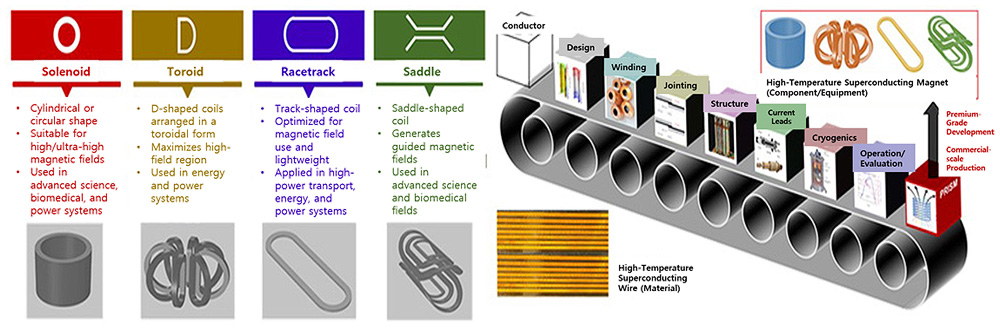

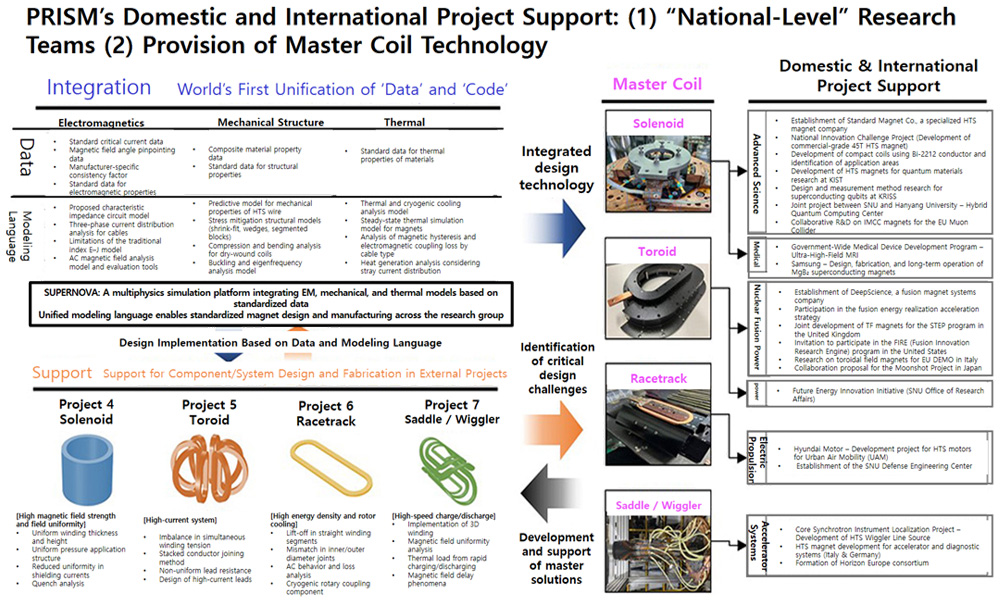

As illustrated in Figure 8, PRISM has developed the world's first systematized research framework by categorizing HTS magnets into four fundamental geometries-solenoid, toroid, racetrack, and saddle-and seven key enabling technologies-design, winding, jointing, structure, current leads, cryogenics, and operation/evaluation. To unify all participating Korea's institutions into a single, collaborative team, the research group is also working to standardize the language and data across all participating organizations-maximizing efficiency and fostering synergy at the national level.

3-2. Major Achievements of the HTS Magnet Core Technology Research Group (PRISM)

As illustrated in Figure 9, the PRISM research group has successfully unified Korea's leading superconducting researchers into a single team and established the world's first systematic research framework for HTS magnet-categorized by four fundamental geometries and seven key enabling technologies. This integrated system is now being actively applied across a wide array of HTS-based application sectors, both domestic and international, including biomedical, electric propulsion, energy and power systems, national defense, and transportation.

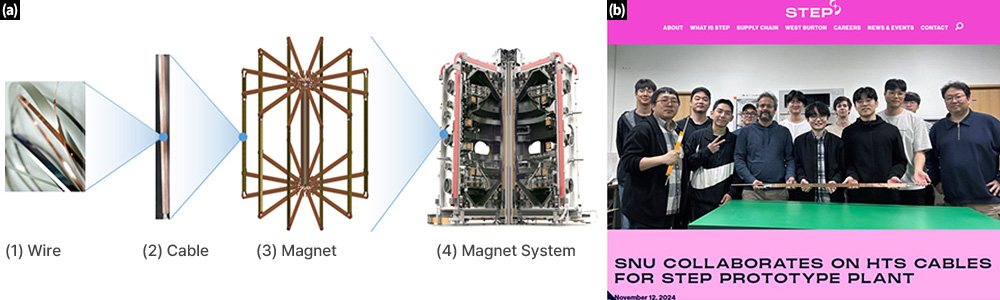

A representative case is the participation of PRISM-affilated companies Powernics Co., Ltd. and Standard Magnet Co., Ltd.-led by a team at Seoul National University-in the UK's STEP (Spherical Tokamak for Energy Production) nuclear fusion program, organized by the United Kingdom Atomic Energy Authority (UKAEA). The research team officially joined the project in March 2024, based on their development of a high-current HTS cable for toroidal magnets, one of PRISM program's key output.

STEP is a large-scale national initiative in the UK, led by UKAEA's subsidiary, UK Industrial Fusion Solutions (UKIFS), and aims to construct the world's first commercial fusion power plant by 2040.

In Phase 1 (March 2024 - March 2025), the team signed a £1 million joint research agreement with UKAEA to develop a 3.6-meter, 100 kA-class high-current HTS cable. In Phase 2 (March 2025 - August 2026), the project scope will expand to the development of a 30-meter cable for the final STEP magnet system. Future plans include scaling the technology toward a full magnet system (see Figure 10).

High-Temperature Superconducting (HTS) Technology and Its Applications in National Defense

4-1. HTS-Based Electric Propulsion Technology

High-Power Density Motors for Naval Electric Propulsion

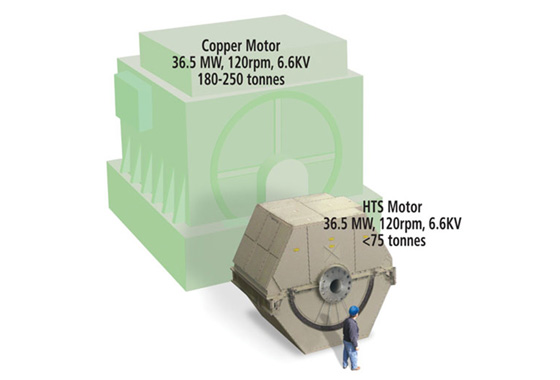

Naval propulsion systems are achieving groundbreaking advancements through the integration of HTS technology. HTS magnets allow the transmission of high currents with minimal heat generation, thereby maximizing motor output efficiency. A notable example is American SuperConductor (AMSC), which developed a 36.5 MW, 120 rpm HTS motor that achieved twice the performance of existing naval propulsion systems in full-load tests in January 2010, while also reducing system size (Figure 11). Research on HTS-based rotating machinery for marine propulsion continues to progress globally. Siemens, for instance, completed a 4 MW-class HTS motor for marine propulsion in 2010 and is currently developing a 16 MW-class system. These developments are ushering in a new paradigm in large-vessel propulsion: low-speed, high-torque operation enabled by HTS technology.

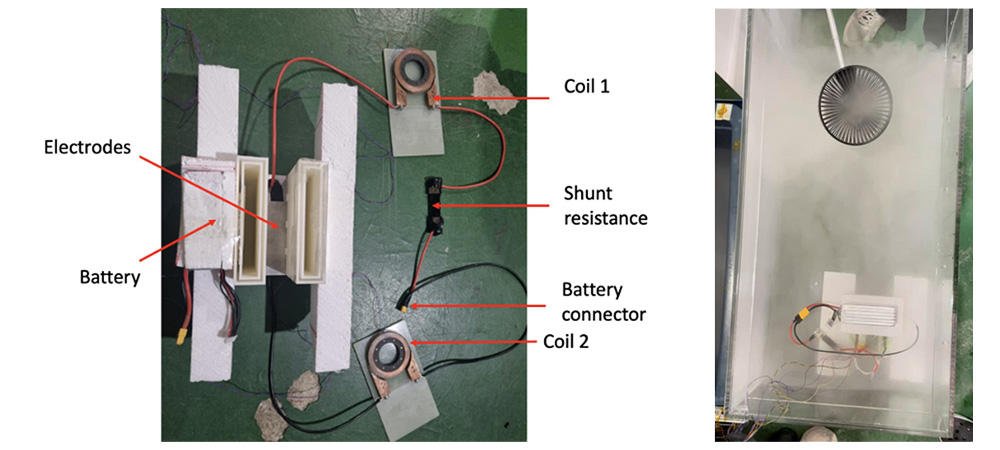

Magnetohydrodynamic (MHD) Propulsion

Magnetohydrodynamic (MHD) propulsion represents an innovative approach that departs from conventional mechanical propulsion systems. It generates thrust by applying electric and magnetic fields directly to an ionized fluid such as seawater-without any mechanically moving parts. Due to its silent operation and lack of mechanical noise, this technology is being considered for stealth submarines. However, achieving sufficient propulsion performance in MHD systems requires the application of strong magnetic fields. The Applied Superconductivity Laboratory at Seoul National University recently demonstrated the feasibility of MHD propulsion using a no-insulation HTS magnet, as shown in Figure 12. Based on actual experimental measurements, the team also presented the potential scalability of this approach to large-scale MHD propulsion systems.

4-2. Defensive and Response Technologies

Electromagnetic Pulse (EMP) Weapons

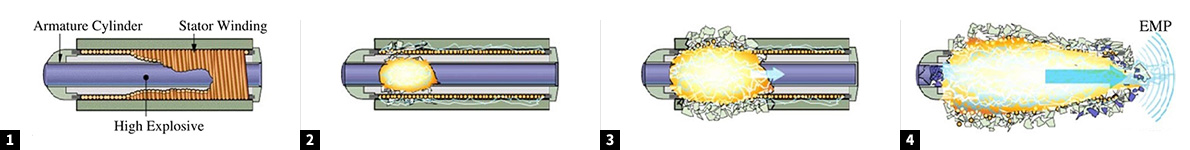

Electromagnetic pulse (EMP) bombs disable electronic circuits by emitting powerful bursts of electromagnetic radiation. These devices operate by generating intense magnetic fields through high-current pulses derived from external power sources. As illustrated in Figure 13, a typical explosive-type EMP system comprises a metallic cylinder, an explosive charge, and a magnet field coil. Upon detonation, the explosive propels the metal cylinder, inducing a rapid compression of the magnetic field within the coil. This dynamic process significantly amplifies the magnetic flux, which is then suddenly released in the form of an electromagnetic pulse (EMP). HTS-based ultra-high-field compact magnets are expected to substantially enhance the performance of EMP systems.

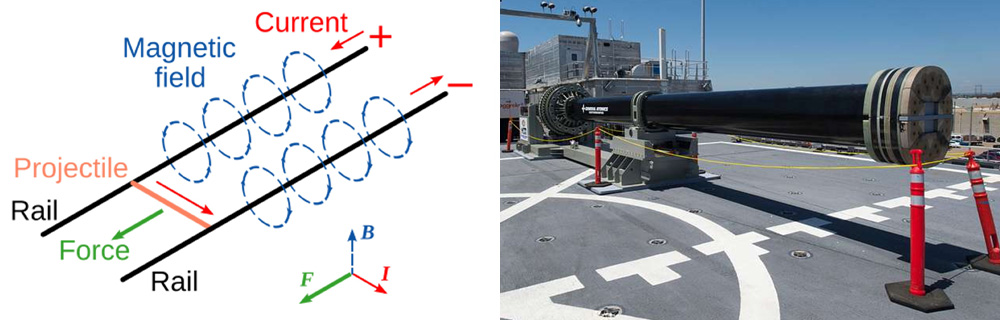

Railgun Pulse Electromagnetic Launcher

Railguns are electromagnetic launch systems that fire projectiles by converting stored energy into high pulse currents (Figure 14). These pulse currents generate strong electromagnetic forces that accelerate the projectile along conductive rails to hypersonic speeds. The U.S. Navy's railgun achieves a muzzle velocity of 7,200 km/h (Mach 6) and a target range of 200 km. To operate, the system requires peak power exceeding 25 MW (33 MJ per shot). HTS technology is expected to play a critical role in enabling core components of railgun systems-near-permanent magnetic energy storage and high-current, low-loss transmission cables for pulse power delivery.

High-Power Motors for Anti-Drone Applications

One of the key features of modern warfare is the use of drones, as illustrated in Figure 15. To counter military drone attacks, a widely adopted strategy is the so-called ‘hard-kill' approach, which involves physcially neutralizing the drones via collision or explosive force. Unlike traditional missile-based interception, hard-kill methods are reusable and typically rely on kinetic energy impact. In this approach, interceptor drones are deployed to directly crash into enemy drones, forming the basis of emerging anti-drone solutions. Various defense companies, including the U.S.-based firm Anduril, are conducting research to develop technologies that can counter drones.

To intercept agile and high-speed attack drones, propulsion motors capable of delivering instantaneous high-power output are essential. However, conventional air-cooled drone structures face inherent limitations in dissipating heat during operation. To address this, cryogenic propulsion motors are being developed in conjunction with HTS technology. By optimizing cryogenic cooling performance, it becomes possible to temporarily operate these motors at high output levels, maximizing the effectiveness of hard-kill drones in real-time combat scenarios.

4-3. Naval Stealth and Mine Countermeasure Technologies

HTS Cable-Based Magnetic Mine Neutralization

Magnetic mine neutralization using superconducting cables is a technique that eliminates underwater mines by inducing their detonation through a mine-sweeping device. As illustrated in Figure 16, this technique involves deploying 200-300 meters of cable along the sea surface, which is towed by a mine-sweeping vessel or a helicopter. An electric current is passed through the main cable to generate a simulated magnetic field, effectively triggering the detonation of the mines. When HTS cable technology is applied, the system benefits from significantly reduced cable weight-particularly advantageous in low-voltage, high-current operations. Moreover, the increased flexibility of HTS cables facilitates easier deployment and retrieval in marine environments.

Degaussing Technology for Naval Vessels Using Superconducting Cables

Degaussing technology utilizing superconducting cables aims to reduce the residual permanent magnetism accumulated in naval vessels due to the Earth's magnetic field and onboard electronic devices. This technology is essential for stealth operations, as underwater mines and related detection systems can identify a vessel by its magnetic signature.

As illustrated in Figure 17, degaussing facilities are typically installed at naval docks, where ships periodically berth for magnetic field neutralization. Conventional systems use copper cables to apply alternating current. In contrast, the application of HTS cables enables the transmission of significantly higher currents, offering advantages such as system size reduction, simplified power infrastructure, and lower operational costs. This technology is currently under active investigation by the Japanese Research Association for Naval Magnetic Signatures in Underwater Environments.

Ship Desensitization Technology Using Superconducting Cables

Desensitization technology, similar to degaussing, aims to suppress a ship's magnetic signature. Unlike degaussing systems, desensitization involves installing cables within the vessel itself, as shown in Figure 18, enabling real-time mitigation of magnetic field.

In shipboard desensitization systems utilizing superconducting cables, the integration HTS components dramatically reduces system weight, installation space, power requirements, and energy consumption compared to conventional systems.

The U.S. Navy has been pursuing long-term development of HTS-based desensitization technology since the early 2000s. In 2021, it signed a contract with American Superconductor Corporation-a major HTS wire manufacturer-to acquire HTS-based desensitization technology.

In Korea, the PRISM research group is currently collaborating with the United Kingdom Atomic Energy Authority (UKAEA) to develop 100 kA-class high-current HTS cables. These cables are intended for use in integrated naval systems for mine neutralization, degaussing, and desensitization.

Conclusion

Since the discovery of high-temperature superconductors (HTS) in 1986, the technology has been regarded as a promising solution for broad industrial applications, thanks to its lower cooling and operational costs compared to low-temperature superconductors (LTS). However, due to the technical challenge of quench events-sudden loss of superconductivity-practical HTS applications remained nearly nonexistent until the early 2010s.

A major breakthrough came in 2009 when MIT introduced the concept of non-insulated (NI) HTS magnets. This approach offered a new paradigm for addressing quench events and has since evolved into a wide range of designs now being applied across diverse manufacturing sectors.

In Korea, the Ministry of Science and ICT launched the HTS Magnet Core Technology Project (2022-2026), under which the PRISM Research Group was established at the College of Engineering, Seoul National University. The consortium includes 27 institutions and over 220 researchers working collaboratively at a world's highest level.

PRISM is the first group globally to systematically classify HTS magnet technology into four representative geometries and seven core technological components. It is also the first initiative to prioritize both mass production and premium-grade refinement of HTS magnets as core infrastructure technology.

Leveraging this world-first nationwide research and education framework, PRISM has produced a variety of cutting-edge technical achievements. Notably, commercialization efforts are expanding into high-impact sectors such as biomedicine, healthcare, defense, electric propulsion, nuclear fusion, and power systems.

Among these, the defense sector is expected to be the earliest adoptor of HTS magnet technology. Active research is already underway in numerous applications, including electric propulsion systems for large naval vessels, magnetohydrodynamic (MHD) stealth propulsion, high-power motors for anti-drone systems, electromagnetic pulse (EMP) weapons, railguns, mine neutralization systems, and ship degaussing and desensitization systems.

References

- 1) Hahn, S., Kim, K., Kim, K., et al. (2010). HTS pancake coils without turn-to-turn insulation. IEEE Transactions on Applied Superconductivity, 21(3), 1592-1595.

- 2) Hahn, S., Kim, K., Kim, K., et al. (2019). 45.5-tesla direct-current magnetic field generated with a high-temperature superconducting magnet. Nature, 570, 496-499.

- 3) H&B Partners. (2024). Development of TRUST: Highly Reliable Ultra-High Magnetic Field High-Temperature Superconducting Magnet. Interim Report on the Planning Study for the Innovative Challenge Program

- 4) Hartwig, Z., et al. (2023). The SPARC Toroidal Field Model Coil Program. arXiv preprint arXiv:2308.12301.

- 5) KAEA. SNU collaborates on HTS cables for STEP prototype plant. Retrieved December 20, 2024, from https://step.ukaea.uk/snu-collaborates-on-hts-cables-for-step-prototype-plant/

- 6) La Rosa Betancourt, M., Ballester, B. M., O'Regan, R., et al. (2019, May). UDT 2019-Technology trends and challenges for superconductor-based ship propulsion. In Proceedings of the 32nd Undersea Defence Technology Conference (pp. 13-15). Stockholm, Sweden.

- 7) Koo, K., Im, C., Kim, G., Kim, J., Hahn, S., & Lee, S. (2024). Design, construction, and operation of liquid nitrogen cooled MHD miniature ship with no-insulation high temperature superconductor magnet. IEEE Transactions on Transportation Electrification.

- 8) Brain, M. How E-Bombs Work. HowStuffWorks. Retrieved December 20, 2024, from https://science.howstuffworks.com/e-bomb3.htm

- 9) Defense Visual Information Distribution Service. Retrieved December 20, 2024, from https://www.dvidshub.net/

- 10) Wikimedia Commons. Railgun-1.svg. Retrieved December 20, 2024, from https://commons.wikimedia.org/wiki/File:Railgun-1.svg

- 11) Rawpixel. Retrieved December 20, 2024, from https://www.rawpixel.com/image/3393500

- 12) The U.S. National Archives. Retrieved December 20, 2024, from https://catalog.archives.gov/

- 13) McLain, J. U.S. Navy Photograph.

- 14) National Museum of the U.S. Navy. Retrieved December 20, 2024, from https://www.history.navy.mil