Recent climate change poses a threat to the future of mankind, and there have been global efforts to tackle the emission of Greenhouse Gases (GHG). International Maritime Organization (IMO) has decided to initiate its regulation to reduce carbon emissions within the shipping industry and has made significant changes in the ship and offshore industries. In 2018, IMO selected its initial GHG strategy, which requires a 40% reduction of carbon intensity by 2030 from ships and a 70% reduction by 2050. Most current ships operate on Heavy Fuel Oil (HFO), so the carbon emission problem is critical.

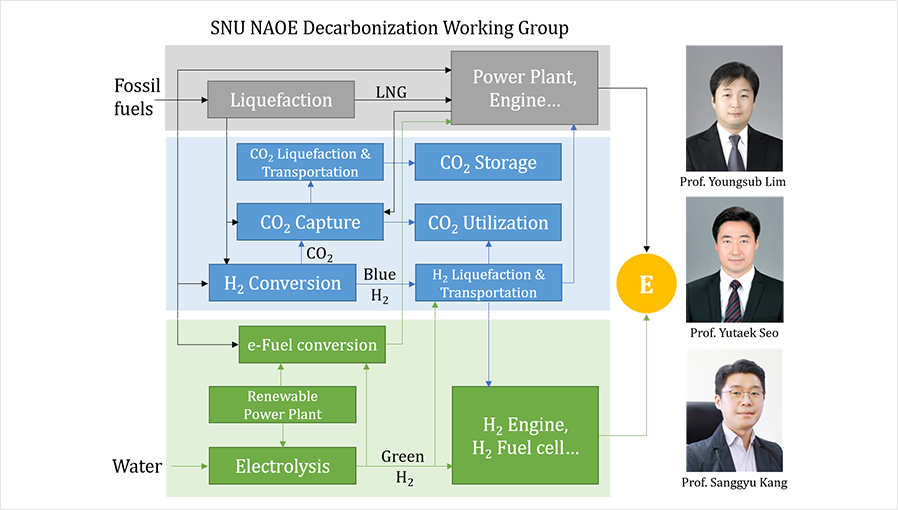

Professor Sanggyu Kang, Youngsub Lim, and Yutaek Seo in the Department of Naval Architecture and Ocean Engineering (NAOE) formed an “NAOE Decarbonization Working Group” to solve these problems. The working group aims at a collaboration research on the lifecycle of alternative fuels; the research includes the production, liquefaction, transportation, and distribution of LNG, LPG, methanol, hydrogen, and ammonia. It also includes studies on the Carbon Capture, Utilization, and Storage (CCUS) technologies required for a ship and an alternative fuel supply chain.

Figure 1 Scheme of the SNU NAOE Decarbonization Working Group

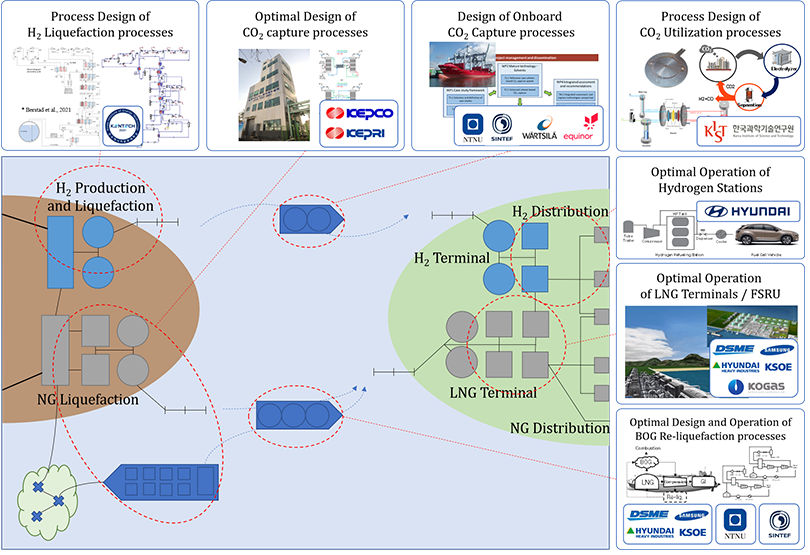

Professor Youngsub Lim has been researching gas processing systems, including natural gas liquefaction, CO2 capture, utilization, hydrogen production, and liquefaction processes.

Natural gas, a representative low-carbon emission fuel, is expected to be one of the promising alternative fuels in the commercialization of carbon-neutral fuels. The importance of natural gas will increase, especially since the current hydrogen production is mainly based on natural gas reforming. Prof. Lim’s research team has focused on efficient LNG supply chains, including NG production and liquefaction, LNG bunkering, and BOG re-liquefaction processes.

Many people discuss the use of green hydrogen and e-fuel; however, more than 90% of hydrogen is still made from fossil fuels. Therefore, the sector requires more efficient methods of production, liquefaction, and distribution of hydrogen for the era of green hydrogen. The production and liquefaction processes of hydrogen are extremely energy-intensive, so the economic feasibility of the hydrogen supply chain can be greatly increased by enhancing the efficiency of these processes. The operating strategy of the hydrogen transportation and distribution process is also critical. Therefore, Prof. Lim’s research team has been researching more efficient process design and operation for hydrogen production, liquefaction, and distribution.

CCUS has recently been mentioned as a possible application to reduce carbon emissions from ships. There has been a lot of research about onshore CCUS, but the commercial application has yet to be adopted for ships. The absorbent-based CO2 capture process using amine solutions, a conventional process, may be applicable. However, the difference in the CO2 concentration in the exhaust gas, the limitation of space, and the motion effect of a ship on a column might affect the process and thus need to be studied in depth. Moreover, the conventional CO2 liquefaction and transportation processes have only handled high purity of CO2, but the CO2 from various capture processes may have unexpected impurities. Currently, the economically feasible way of hydrogen production is reforming fossil fuels such as methane, a major component of natural gas. Reforming methane, nevertheless, generates CO2, meaning it cannot be an environment-friendly solution without CCUS. Prof. Lim’s research team has focused on an efficient carbon capture process that considers the energy, cost, and space limitations and efficient CO2 liquefaction process linked with capture processes.

Figure 2 Natural gas and carbon dioxide research area (Y. Lim).

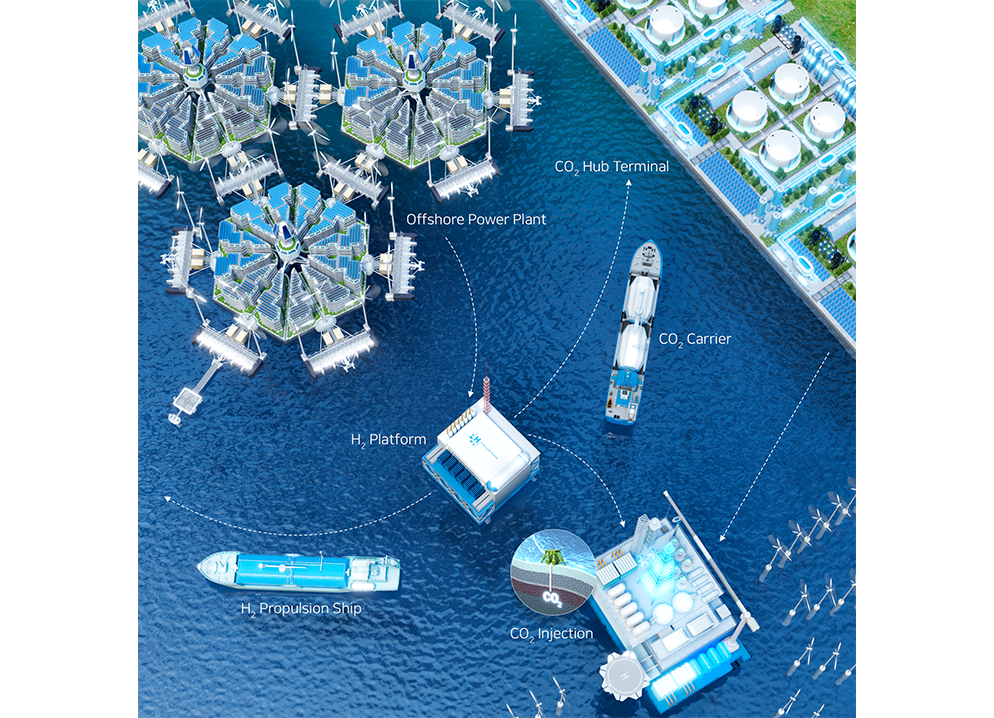

Professor Yutaek Seo is developing a floating platform to capture, store, and offload CO2 from the sources to the sinks.

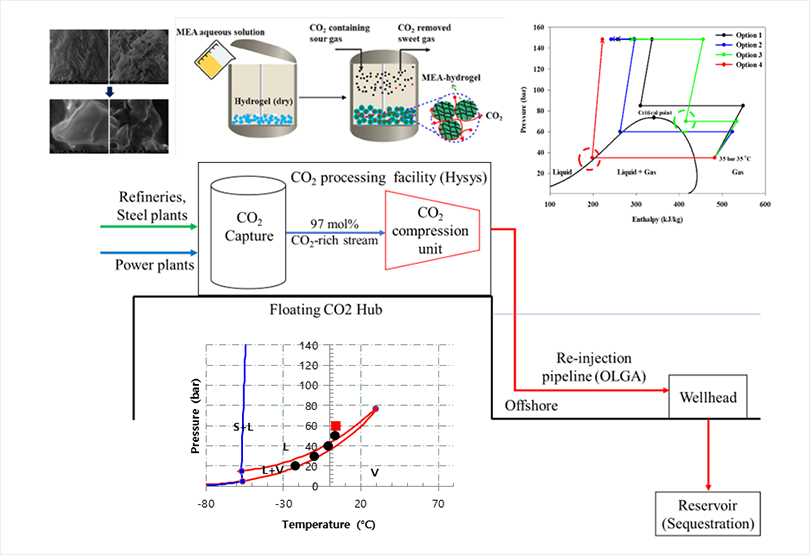

Great efforts have been made to develop Amine-based CO2 capture processes and CO2 injection technologies. However, there is a need to establish a CO2 transportation network globally: the distance between the CO2 sources and the CO2 injection sites is very long, and pipelines cannot be constructed. In the case of the Korean peninsula, most CO2 sources are located in the coastal area, but the injection sites are limited to offshore in the West and East sea areas. Due to the highly populated cities, constructing CO2 transport pipelines onshore may be difficult, thus demanding the mobile CCS platform along the coastal area.

The Floating CO2 hub will play the role of the central facility in the CO2 network as it connects the CO2 capture sites and its injection sites by temporarily storing CO2 in cryogenic conditions and exporting the CO2 through the newly developed large-scale CO2 carrier. The hub can also capture CO2 from the post-combustion as well as pre-combustion gases delivered to the hub via pipelines. Just smartphones with many applications downloaded, the Floating CO2 hub will have on-demand CO2 capture, storage, and offloading processes, optimized for CO2 emission and injection characteristics of the deployed area.

Conventional technologies are robust and well-proved, but researchers continue to investigate advanced technologies to improve the efficiency and applicability of CO2 handling technologies. The hydrogel polymers infused with amine solutions provide a large surface area to capture CO2 from gas streams, reducing the footprint and complex rotating machines. The temperature and pressure of CO2 storage tanks must be controlled precisely to avoid the CO2 formation, which determines its wall thickness to minimize the CAPEX. Dynamic operations for handling liquid-phase CO2 on a large scale would induce many control problems, such as minimizing boil-off gas with pressure management. During the long-distance transport of CO2 via subsea pipelines, flow assurance issues like unstable flow regimes, Joule-Thomson cooling, and gas hydrates blockage formation may arise.

The research team focused on the design of not only the floating CO2 hub that will play a key role in the mobile CCS platform but also the pipeline network. Both experimental and modeling works have been under investigation, along with domestic and international research partners worldwide. Currently, the research team is developing the hub for the East Sea of Korea but will soon develop platforms that work on international waters. Moreover, the Floating CO2 hub can expand to produce green alternative fuels, like methanol and ammonia, when the hydrogen supply line is connected to the onboard synthesis units. This system can be a game changer for advancing the energy supply chains and CCS network.

Figure 3

A floating CO2 hub is a central facility that captures, stores,

and offloads CO2 from the sources to injection sites.

Amine-infused hydrogels are employed to capture CO2.

Phase changes and flow characteristics were under investigation

for the Floating CO2 hub in the East Sea of Korea.

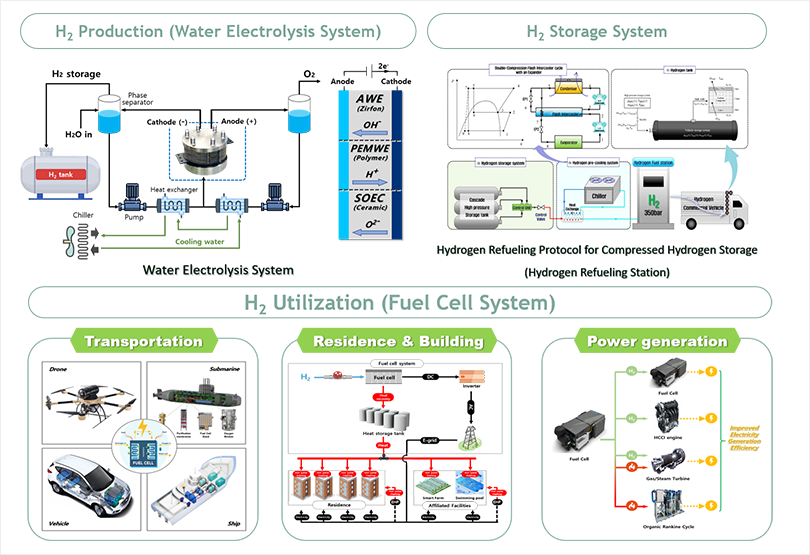

Professor Sanggyu Kang has been researching intelligent hydrogen energy systems, including hydrogen production (AWEC, PEMEC, and SOEC), hydrogen storage (Compression, Liquefaction, LOHC, and Ammonia), hydrogen utilization (PEMFC, PAFC, and SOFC), and smart energy management system (Smart-grid and VPP).

The imbalance between supply and demand due to the intermittency and unpredictability of renewable energy sources must be resolved to expand the renewable energy grid. Water electrolysis technology is a promising method for energy storage, which is appropriate for long-term and high-capacity energy storage. The alkaline water electrolysis has reached the highest technology readiness level (TRL), followed by proton exchange membrane electrolysis and solid oxide electrolysis cell. SOEC leads in H2 production efficiency, followed by the PEMEC and the AWEC. PEMEC shows the greatest dynamic response, and AWE and SOEC follow. Since the H2 production efficiency of the water electrolyzer using renewable power sources highly depends upon this system’s dynamic response, PEMEC has been deployed the furthest and developed rapidly over the past decade.

However, the levelized cost of hydrogen (LCOH) of most water electrolysis technologies is still expensive compared to other conventional H2 production technology types, such as steam methane reforming (SMR). To satisfy the target price of LCOH, H2 production efficiency and dynamic system response of the water electrolysis system should be significantly improved. Fuel cells are strong candidates for clean power generation devices, compared to conventional power generation devices, due to their high electrical efficiency and low emission of air pollutants such as CO2 and NOx.

Solid oxide fuel cell (SOFC) has the highest system electrical efficiency; molten carbonate fuel cell, phosphoric acid fuel cell, and proton exchange membrane fuel cell follow after. However, among other types of fuel cells, the SOFC has the lowest TRL and lifespan. Many researchers have focused on developing a highly efficient and endurable fuel cell system so that the fuel cells hold competitive against conventional power generation.

The research specialties of Prof. Kang’s research team show strengths in technologies regarding system engineering (energy, exergy, techno-economic, and exergoeconomic analysis), physical-digital twin, life cycle assessment (LCA), computational fluid dynamics (CFD), data-driven digital twin, and experiment. System engineering aids in obtaining optimal system design and optimal operating conditions. Investigating dynamic system behaviors using physical-digital twins develops optimal control strategies during start-up, load-change, and emergency shut-down. Techno-economic analysis helps discover the dominant factor that determines LCOH and LCOE. LCA determines quantitative greenhouse gas reduction of the proposed novel system, CFD achieves optimization for the geometric dimension of component devices, and the data-driven digital twin demands load and establishes renewables power generation profiles. Smart-grid and VPP enable optimization for energy distribution and trading. Through experimental evaluation, Prof. Kang’s research team has been trying to prove their proposed novel system design and digital twin technologies.

Figure 4 Hydrogen research area (S. Kang)