Eco-friendly power generation using waste heat

Laying the groundwork for commercialization of high-performance, low-cost thermoelectric technology

Professor In Chung

Professor In Chung's team of the Department of Chemical and Biological Engineering has succeeded in developing a new thermoelectric material that has the world's highest power generation efficiency without containing highly-priced or toxic elements.

More than 65% of the energy produced worldwide is lost as heat, also known as waste heat. Electricity generation is completely dependent on fossil fuels, and the process of recovering vast amounts of waste heat that can be regenerated into a usable form of energy is an absolutely crucial factor that solves energy and environmental challenges that we face in the world today.

Since thermoelectric technology directly converts thermal energy into electrical energy in a simple semiconductor device, it does not generate any mechanical noise, vibration, or harmful chemicals. Therefore, thermoelectric technology has been considered a cutting-edge technology that can simultaneously cope with energy and environmental problems.

In fact, thermal power was the main energy source of the spacecraft to the Mars that the United States launched twice, and the thermoelectric power generator was introduced as an energy source in the movie 'Martian,' starring Matt Damon.

However, high-performance materials developed so far contain elements such as toxic lead and rare tellurium, making their commercialization impractical due to the environmental and economical problems.

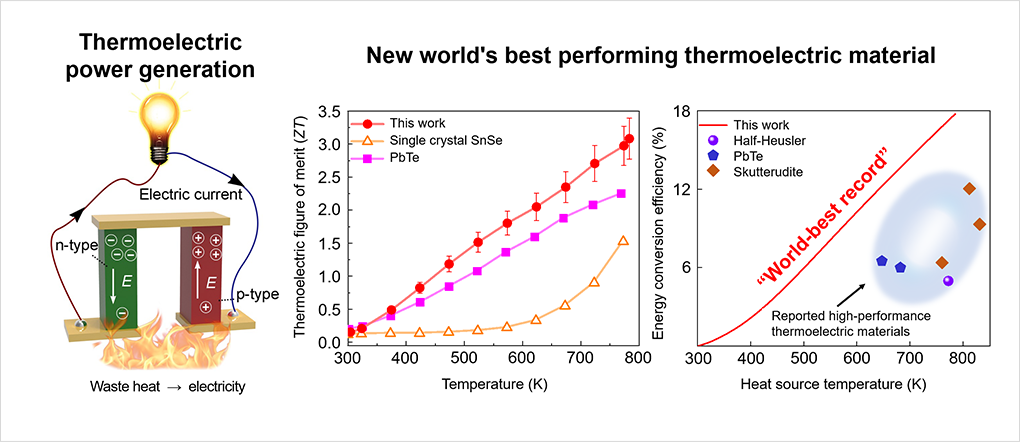

Figure Image displaying research achievements

Professor In Chung's team at Seoul National University's School of Chemical and Biological Engineering solved this problem by developing ultra-high-performance polycrystalline materials based on tin (Sn) and selenium (Se) elements. Tin selenide attracted great attention in 2014 because this material showed very high thermoelectric performance index (ZT) of 2.6 in the form of single crystals. However, the reproducibility of the results has been a big controversy up until now.

In addition, single crystal materials cannot be produced in large amounts due to its labor-intensive and long-term high-cost manufacturing process, and its difficulty of commercialization due to mechanical defects. To solve this problem, research on tin selenide polycrystalline material was conducted worldwide due to its advantages for industrialization. However, it showed very low efficiency compared to single crystal materials.

In this study, a new synthetic process was developed to identify the fundamental cause and to provide solutions for polycrystalline materials having low performance. As a result, the new material exhibited ultra-high generation performance with a thermoelectric performance index of over 3.1 for the first time in history, and the power generation efficiency that converts thermal energy into electrical energy exceeded 20%, a new world record.

"As perovskite materials have created major shifts in solar cell research, the new polycrystalline SnSe-based material has opened a new horizon for commercialization of ultra-high-performance generation of thermoelectric power," emphasized Professor In Chung. He has developed the world's first perovskite-based all-solid-state solar cell.

Meanwhile, the research results, supported by the National Research Foundation of Korea's Nano/Material Source Technology Development Project and the Mid-Sized Research Project were published in the latest online issue of 'Nature Materials' on August 3.

For further information, please contact Prof. In Chung.