Development of anodic oxide electrodes with ordered and self-supported nanoarchitecture

Structural modifications for enhanced performance in photoelectrochemical cells

Compositional and morphological changes to achieve high electrocatalytic activities

Professor Jin Soo Kang in the Department of Energy Resources Engineering and Department of Energy Systems Engineering has been developing nanostructured anodic oxide electrodes for electrochemical energy applications, ranging from (photo)electrochemical hydrogen production to electrocatalytic CO2 conversion.

A shift in the energy paradigm is gradually taking place with a global aim of carbon neutrality within a few decades. Fossil fuels with extremely large energy density have served as the major energy resources for mankind, and indeed, they should be credited for substantial development since the breakout of the industrial revolution. Meanwhile, the production of CO2 is unavoidable when using fossil fuels. The rise in the atmospheric concentration of greenhouse gases (mainly CO2) is widely accepted as the main origin of global warming and climate change, of which adverse effects are encountered in many places around the world.

In order to address the climate-change issue, many leading countries announced their target years for realizing carbon-neutral energy production. The strategies to achieve the goal include increasing the portion of renewable and nuclear energies, accompanied by storing the produced energies for their efficient utilization. Electrochemical systems play key roles here, as the variation in their function can be done simply by modifying/changing the electrode(s) and the electrolyte. For instance, an appropriate pair of lithium-storable electrodes constitute lithium-ion batteries, and the incorporation of semiconductor photoelectrode(s) may lead to solar-to-electrical or solar-to-chemical energy conversion. In most of the systems, the physicochemical properties of electrode materials have a substantial influence on the overall performance.

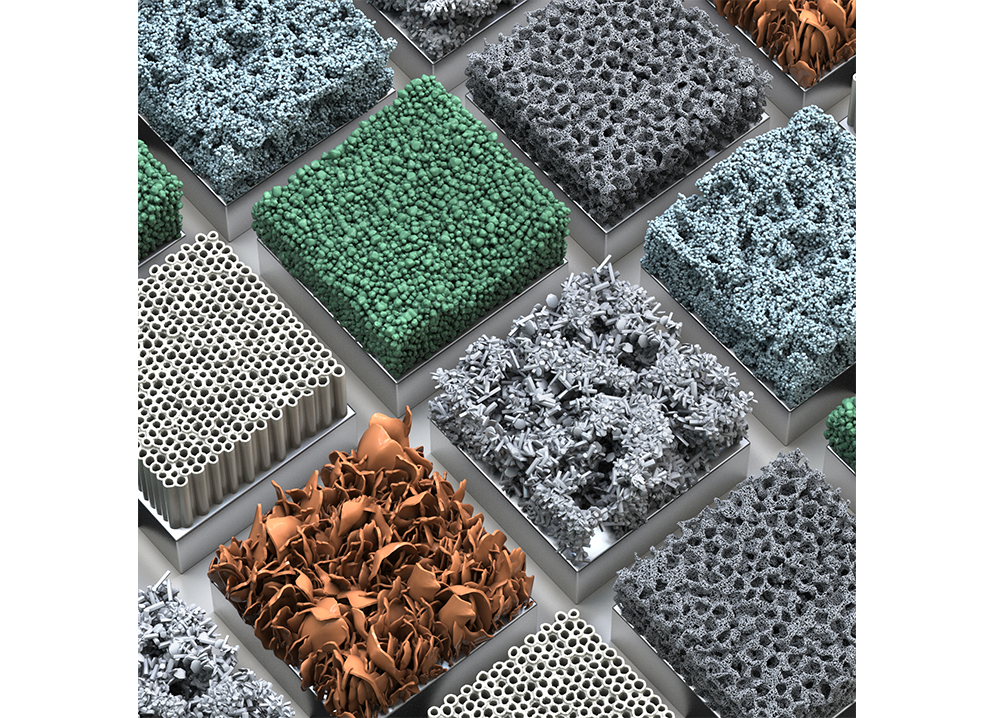

Prof. Kang has developed electrode materials prepared by anodic oxidation (or anodization) with a wide range of structures and compositions. This method, which could be understood as a controlled electrochemical corrosion of a metallic substrate, enables the synthesis of (roughly) ordered oxide nanoarchitectures. Based on the composition and anodization conditions, a variety of structures can be materialized at a small scale. These oxide materials are useful as electrode materials for diverse energy conversion and storage devices, as depicted in Figure 1, which shows the summary of progress achieved by Prof. Kang and co-workers.1-8

In order to further enhance the performance and versatility of this group of electrode materials, two strategies were additionally taken. First, in order to increase the active surface area for light-harvesting and electrocatalytic reactions, two-dimensional metal foils that are conventionally used for anodic oxidation were replaced by three-dimensional metallic foam substrates. As a result, a dramatic increase in the operation rate (represented by the current density in electrochemical systems) was achieved, especially in photoelectrochemical cells whose performance is mostly limited by light-harvesting properties under a given light source (e.g., sun).2,3

Another approach was to convert the oxide materials into other types of compounds by post-treatment of the synthesized anodic oxide. Based on the understanding that transition metal carbides have electronic structures similar to platinum, anodic oxides were thermally treated by using a carbon-containing gas, which enabled a complete change of oxides to carbides. These carbide electrodes manifested decent activity in hydrogen evolution reactions, with highly reliable performance up to thousands of electrochemical sweeps.4,5

Besides the excellent feasibility of nanostructured electrodes prepared by anodic oxidation, anodization itself is intrinsically a favorable synthetic technique for electrochemical systems, for the resulting oxide is generally self-supported and is strongly adhered to the conductive substrate. This reduces the number of steps in electrode manufacturing processes and improves the durability of electrodes. Using anodization as a platform for electrode preparation, Prof. Kang is working on a deeper understanding of reaction mechanisms, microscopic control of anodic compounds, and expanding the fields of their applications in order to advance the realization of carbon neutrality.

Figure

Microscopic structures of various anodic oxides and their derivatives

and the fields of applications toward carbon neutrality

(the electron microscope images are adapted from references 1-5, 7, 8, and the graphical illustrations are adapted from references 2, 4, 5, 8).

References

- 1. J.-Y. Kim, J. S. Kang et al. Nanoscale 2015, 7, 8368-8377.

- 2. J. S. Kang et al. Small 2017, 13, 1701458.

- 3. J. S. Kang et al. Angew. Chem. Int. Ed. 2017, 56, 6583-6588.

- 4. J. S. Kang, J. Kim, M. J. Lee et al. Nanoscale 2017, 9, 5413-5424.

- 5. J. S. Kang, J. Kim, M. J. Lee et al. Adv. Sci. 2018, 5, 1700601.

- 6. J. Kim, J. S. Kang et al. J. Power Sources 2018, 396, 213-219.

- 7. J. S. Kang, J. Kim et al. ACS Appl. Energy Mater. 2018, 1, 4178-4185.

- 8. J. Jeong, J. S. Kang et al. Chem. Commun. 2021, 57, 3445-3448.