"Expected to accelerate the commercialization of battery-free self-powered wearable electronics."

Possibility of mass production of 'Green Energy Harvesting Devices', marketability↑

Professor Yongtaek Hong‘s Team of the SNU Department of Electrical and Computer Engineering:

From left, Professor Yongtaek Hong, Dr. Byeongmoon Lee, and Researcher Hyeon Cho

A skin-attachable, self-powered “energy harvesting” technology that uses body temperature has been developed by domestic researchers. It is a key technology that facilitates self-powered wearable electronics without the need for batteries for the Internet of Everything (IoE).

SNU College of Engineering (Dean Kookheon Char) announced on December 1 that Professor Yongtaek Hong's research team (Dr. Byeongmoon Lee, Researcher Hyeon Cho) in the Department of Electrical and Computer Engineering has developed highly compliant thermoelectric generators with high energy conversion efficiency by simultaneously maximizing the softness and heat transfer ability of the thermoelectric platforms, through joint research with Dr. Seungjun Chung of the Soft Hybrid Materials Research Center at the Korea Institute of Science and Technology (KIST). The research team has commented that their technologies will serve as a catalyst for research on self-powered wearable electronics by enabling the mass production of large-area thermoelectric devices through a fully automated, additive manufacturing process.

Thermoelectric generators are energy conversion devices that utilize the voltage generated from the temperature difference across both ends of materials. They are in the spotlight of eco-friendly energy harvesting devices in that they convert discarded heat energy into usable electrical energy. Recently, flexible or stretchable thermoelectric generators capable of converting waste heat on three-dimensional heat sources into electricity have been widely reported. If such compliant thermoelectric generators are attached to human skin, body temperature alone can operate wearable devices without batteries.

However, in the case of conventional flexible or soft substrates, which are mainly used for compliant thermoelectric generators, the thermal conductivity of the substrates is very low that heat energy cannot be efficiently transferred to thermoelectric materials, which lowers the energy conversion efficiency. Also, the flexibility was limited due to the use of rigid and thick metal electrodes. To address this problem, organic thermoelectric materials with intrinsic flexibility have been actively investigated, but due to their remarkably low thermoelectric performance compared to conventional inorganic-based thermoelectric materials, it has been difficult to apply them to actual wearable devices.

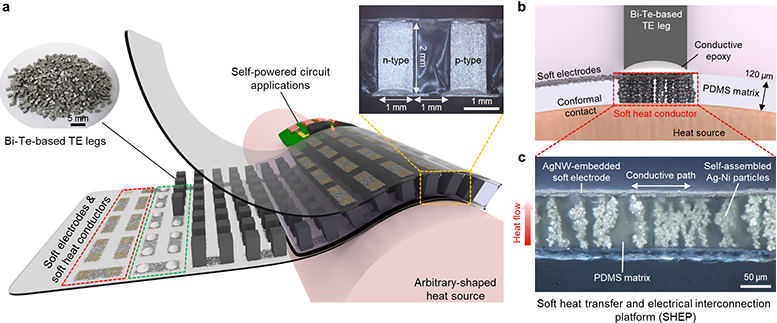

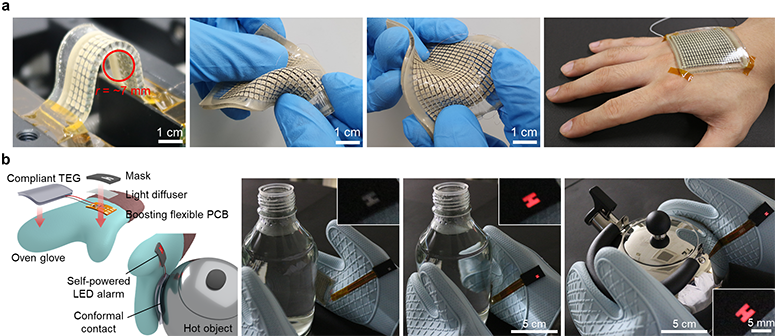

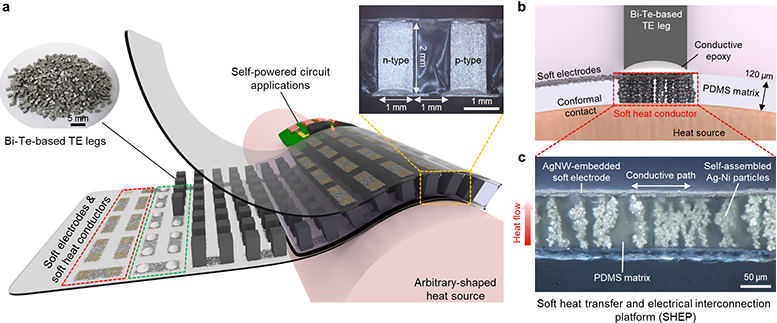

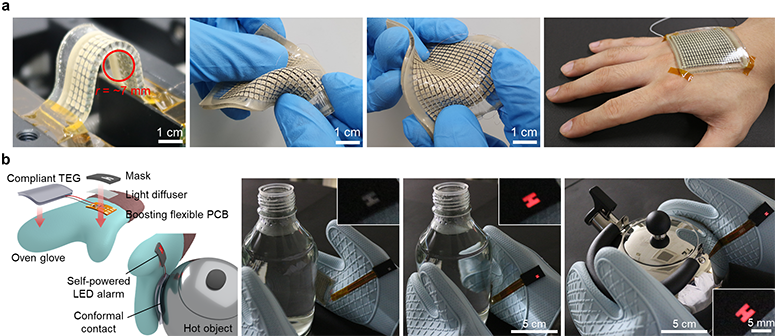

The research team maximized the mechanical conformability of the compliant thermoelectric generators by interconnecting inorganic thermoelectric legs with intrinsically stretchable electrodes. The soft electrode, which consists of a silver nanowire network embedded in an elastomer, has a low Young's Modulus that is comparable to that of rubber and maintains a high electrical conductivity even if it is stretched, enabling the reliable operation of the compliant thermoelectric generators perfectly conforming to various 3D shapes.

In addition, the research team significantly improved the heat transfer ability of the soft platform by forming soft heat conductors through self-assembly of the metal particles inside the stretchable substrates. The soft heat conductors increased the thermal conductivity of the soft platform by 800% (1.4 W/mK) compared to the pristine elastomer, and consequently, power generation of the thermoelectric generator increased by a factor higher than three.

As a result, the thermoelectric generator developed by the research team not only perfectly adheres to the skin, but also minimizes the loss of thermal energy, yielding the world's best power density on human skin.

"This study is meaningful in that a practical, compliant thermoelectric generator that can operate actual wearable devices has been developed by simultaneously increasing mechanical softness and thermal efficiency," said Professor Hong. "It greatly contributes to popularizing battery-free self-powered wearable devices, securing marketability in the future," he added.

The study was published online on November 23 in the renowned international journal Nature Communications. This research was supported by the Ministry of Science and ICT (Minister Choi Ki-Young), and was conducted as part of the Institutional R&D Program of KIST, the Creative Materials Discovery Program of the National Research Foundation of Korea, the Creative Convergence Research Project, Global Frontier Project (Center for Advanced Soft Electronics), and IITP grant (ETRI, Development of Core Technologies for Tactile Input/Output Panels in Skintronics).

(a) Schematic diagram of a highly flexible, high-performance thermoelectric device

(b) Schematic diagram of a soft electrode platform with excellent heat transfer abilities

(c) Metal particles arranged within the soft platform forming a heat transfer path.

(a) Appearance of highly flexible thermoelectric elements that can be freely transformed in shape

(b) A self-powered glove that warns of hot objects by connecting flexible thermoelectric elements with light-emitting elements

For further information, please contact Prof. Yongtaek Hong.