Acquired data required for learning by combining the daily operating sounds of equipment

Expected to provide new ways to build smart factory elements at reasonable costs

From left, Professor Sung-Hoon Ahn and Dr. Ji-Soo Kim

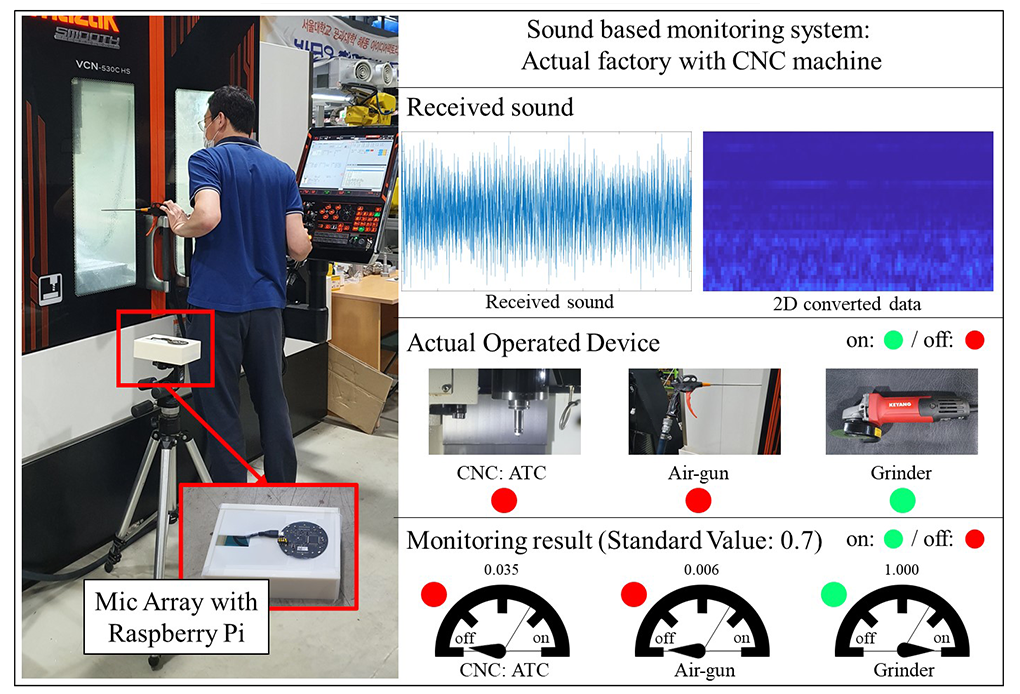

Professor Sung-Hoon Ahn's team of the Department of Mechanical Engineering developed a manufacturing process monitoring system that detects the status of multiple equipment simultaneously in real time, by sound.

This newly developed sensing system converts sound into two dimensions using a log mel-spectrogram through one microphone that is installed in the factory and recognizes it using a Convolutional Neural Network, a type of artificial neural network.

The system is capable of simultaneously tracking the sound of multiple equipment in a very noisy, real factory environment, and unlike conventional methods that involved controlling the behavior of a particular equipment in order to obtain the data needed for learning, this system can combine the daily operating sounds of the equipment to obtain the data.

"Unlike the conventional method that involves the monitoring of only one device by installing sensors inside the equipment, this system aims to monitor multiple devices simultaneously from the outside," said the first author, Dr. Ji-Soo Kim, of the Department of Mechanical Engineering at Seoul National University.

"In general, it is a technology that can monitor the operating time of existing manufacturing equipment for which small and medium-sized enterprises had previously failed to install sensors into due to its costliness. We expect it to be a new solution to build the elements of smart factory at reasonable costs," said the corresponding author, Professor Sung-Hoon Ahn.

The study was conducted with the support of the "Korea-Germany Intelligent Manufacturing Systems Laboratory" project of the National Research Foundation of Korea and the Ministry of Science and ICT and was published in the Journal of Manufacturing Systems. Additionally, the system is currently being applied to different manufacturing environments and processes of small and medium-sized enterprises within Korea.

Figure Examples of equipment monitoring using the systems that were developed

For further information, please contact Prof. Sung-Hoon Ahn.