Professor Kyoungdoug Min, from the Department of Mechanical Engineering, has concentrated on enhancing the efficiency of automotive propulsion systems to advance clean mobility. This includes internal combustion engines, battery systems for electric vehicles, and PEM Fuel Cell (PEMFC) systems, with the goal of achieving fossil-free propulsion. Stringent CO2 regulations of vehicles have prompted the development of carbon-free automotive propulsion systems to mitigate transportation-related carbon emissions.

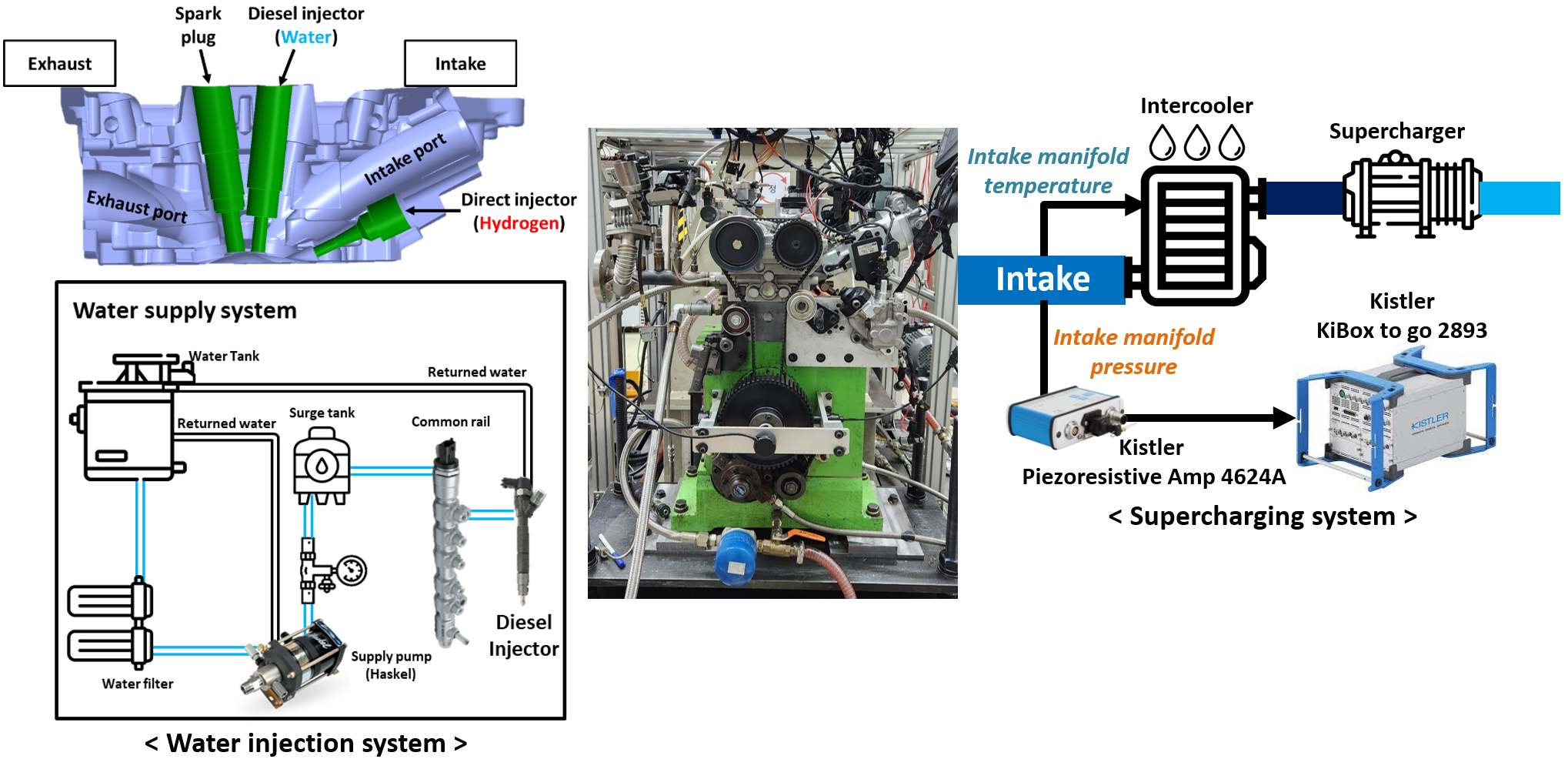

Hydrogen stands out as an optimal fuel for decarbonizing internal combustion engines due to its ability to produce zero CO2 emissions during combustion. Currently, research efforts are focused on optimizing the combustion system for hydrogen in spark-ignited (SI) engines using a state-of-the-art single-cylinder research engine shown in Figure 1. To comprehend the effects of key parameters on combustion characteristics, the compression ratio and stroke-to-bore ratio of the single-cylinder research engine can be adjusted while maintaining a constant displacement volume of 0.5 liters - a unique design feature. Additionally, a direct hydrogen injector and a diesel injector for water injection have been integrated. This work aims to gain a more profound understanding of combustion characteristics, improve thermal efficiency, and expand the engine's load capacity. Comprehensive optimization of various operational parameters has been conducted to enhance both thermal efficiency and load expansion.[1]

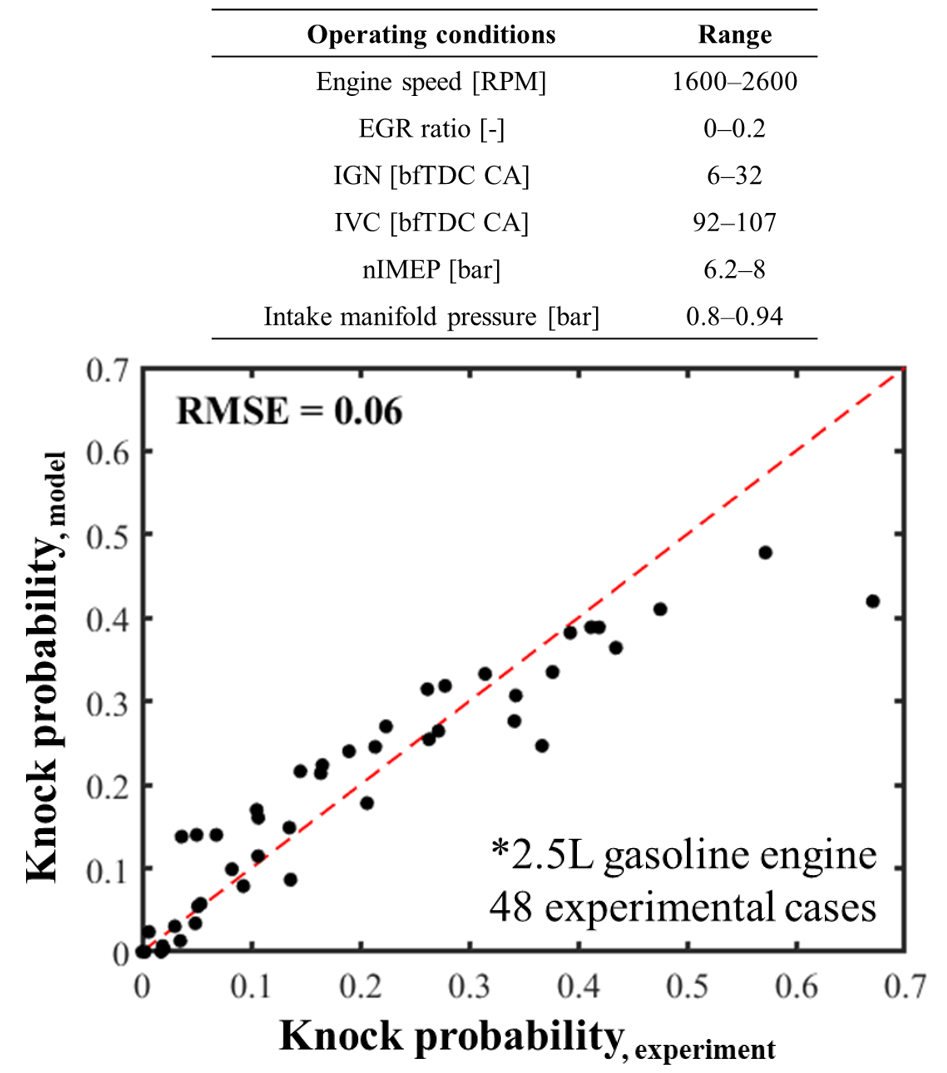

One of the notable challenges in enhancing SI engine efficiency is the occurrence of knocking, which arises from autoignition in the end gas, driven by elevated temperature and pressure. Knocking is a probabilistic phenomenon, rendering it complex to predict. Professor Min has developed a predictive model for knocking using deep learning, specifically by forecasting autoignition timing after determining pre-ignition timing, as shown in Figure 2.[2, 3] This innovative approach harnesses a deep learning model rooted in 1D Convolutional Neural Networks, specialized for feature extraction. The application of this model facilitates precise knocking prediction, significantly contributing to the improvement of SI engine efficiency.

One of the principal strategies for achieving carbon neutrality in automotive propulsion involves increasing the market presence of battery electric (BEVs) and fuel cell electric vehicles (FCEVs). In this context, effective thermal management of BEVs assumes paramount significance, given its direct influence on battery durability, safety, and energy efficiency.

To address this critical issue, a collaborative research laboratory has been established through a longstanding partnership with the Hyundai Motor Group. This laboratory is dedicated to exploring energy management in BEVs, encompassing the analysis of energy flow and the development of advanced cooling methodologies tailored specifically for BEVs.

The primary objective of this initiative is to develop cutting-edge vehicle-level thermal management technology and cultivate a robust research ecosystem for BEV thermal management in Korea. As part of this project, Professor Min's laboratory has been equipped with state-of-the-art facilities for battery experiment. These facilities include a 1000V, 1000A battery pack charger, an environmental chamber designed for the comprehensive evaluation of battery pack system, and two environmental chambers dedicated to single-cell testing (refer to Figure 3).

Research efforts extend to comprehensive simulations at varying levels, ranging from individual cell to battery pack system, aimed at optimizing cooling method and geometric configurations. Advanced cooling systems, including double-sided cooling and immersion cooling, are undergoing rigorous investigation to minimize temperature differentials among battery cells and mitigate temperature elevations.[4] Furthermore, the project encompasses a systematic exploration of the effect of different cooling methods on single-cell performance and degradation. In addition, a model has been developed to enhance the understanding and mitigation of battery thermal runaway, a critical concern for battery safety and reliability.

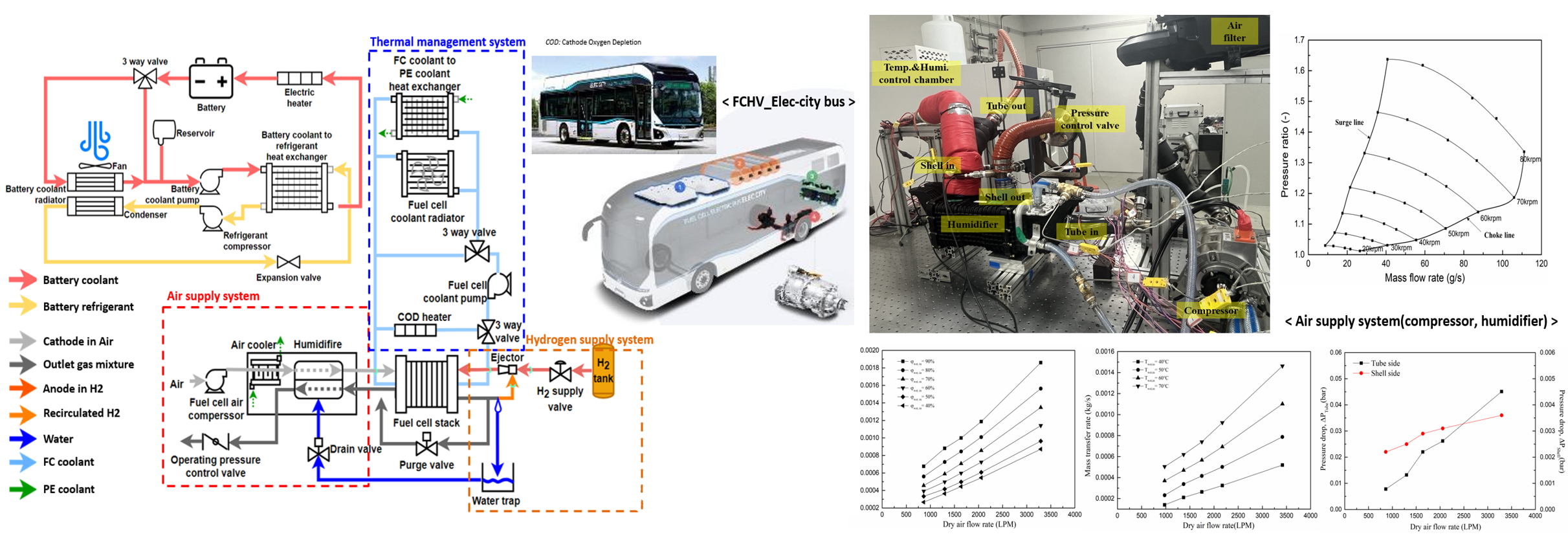

In the pursuit of simulating energy flow and controlling the system of a fuel cell electric bus, a comprehensive modeling approach has been adopted, encompassing the proton exchange membrane fuel cell (PEMFC) system, balance of plant (BOP), battery system, and power module as shown in Figure 4. Furthermore, a thorough analysis of the thermal management system for fuel cell hybrid vehicles (FCHV) has been conducted, complemented by experiment on the BOP components to validate the model.

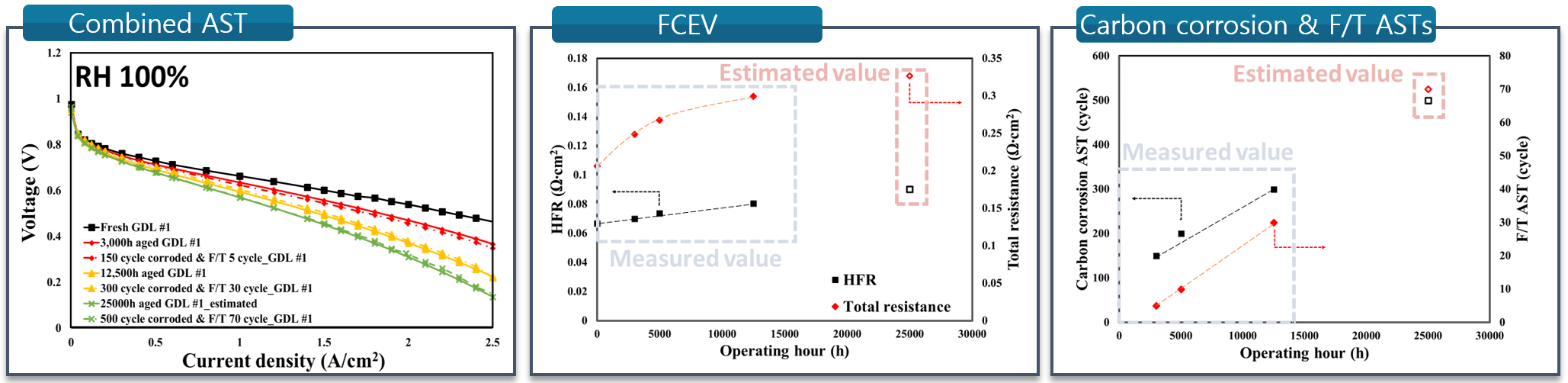

The durability issue of PEMFCs remains of paramount importance on FCEVs. To tackle this challenge, Professor Min has developed an Acceleration Stress Test (AST) designed to expedite the degradation of Gas Diffusion Layer (GDL) within a shorter time frame.[5-7] This AST incorporates freeze/thaw and carbon corrosion cycles to emulate the physical and chemical characteristics of long-term-operated GDLs. The efficacy of these newly developed AST procedures has been evaluated by comparing the performance of GDLs subjected to ASTs with GDLs that have undergone extended operation in an FCEV. This evaluation involves analyzing polarization curves and electrochemical impedance spectroscopy, among other tests. The results demonstrate that the newly developed AST method can effectively simulate the performance of GDLs that have been operated for 3,000, 5,000, and 12,500 hours, offering valuable insights into the chemical and mechanical degradation of GDLs and membrane electrode assemblies shown in Figure 5.

Additionally, a detailed semi-3D modeling of PEMFC using Matlab/Simulink has been developed, enabling the analysis of properties such as current density, temperature, relative humidity, and their distributions within the fuel cell stack.[8-12] This modeling approach, combined with physical property measurements obtained through AST, facilitates the prediction of PEMFC performance and degradation.

Professor Min's research endeavors are multifaceted, with a focus on defossilization of internal combustion engines, enhancing the energy efficiency, safety, and durability of battery electric vehicles. Furthermore, his group is expanding their research scope to encompass energy flow in BEVs and FCEVs to advance the realization of carbon neutrality.

Figure 1 Schematic diagram of experimental set-up for hydrogen combustion experiment

Figure 2

Prediction of knock probability based on deep learning prediction model

of mass burned fraction

Figure 3 Battery test facilities (Battery pack cycler system (left), Battery cell cycler system (right)

Figure 4 Schematic diagram of FCHV modeling and the performance test graphs of BOP system

Figure 5 The results of the combined AST method on PEMFC

References

1. S. Lee, Y. Kim, J. Lee, K. Kim, S. Lee, K. Min, S. Oh. Fuel 2023, 349.

2. J. Park, S. Shin, S. Oh, S. Lee, W. Shin, K. Min. International Journal of Automotive Technology 2023, 24, 1395-1410.

3. J. Park, S. Lee, S. Cho, S. Shin, M. Kim, C. Song, K. Min. SAE Technical Paper 2021, 11.

4. I. Park, H. Choi, K. Min. KSAE Autumn Conference and Exhibition 2023.

5. J. SIM, M. Kang, M. Min, E. Lee, J-Y. Jyoung. Renewable Energy 2022, 190, 959-970.

6. J. SIM, M. Kang, M. Min. Journal of power sources 2022, 544, 231912.

7. J. SIM, M. Kang, M. Min, International Journal of Hydrogen Energy 2021, 46, 27731-27748.

8. J. Cho, H. Oh, J. Park, K. Min. International Journal of Hydrogen Energy 2014, 39, 459-468.

9. J. Cho, H. Oh, J. Park, K. Min. International Journal of Hydrogen Energy 2014, 39, 495-504.

10. J. Park, H. Oh, J. Cho, K. Min. The Korean Hydrogen & New Energy Society Conference 2013, 24, 216-222.

11. H. Oh, Y-I. Lee, G. Lee, K. Min. Journal of Power Sources 2017, 345, 67-77

12. M. Kang, J. Sim, K. Min. International Journal of Hydrogen Energy 2022, 47, 29467-29480.

1. S. Lee, Y. Kim, J. Lee, K. Kim, S. Lee, K. Min, S. Oh. Fuel 2023, 349.

2. J. Park, S. Shin, S. Oh, S. Lee, W. Shin, K. Min. International Journal of Automotive Technology 2023, 24, 1395-1410.

3. J. Park, S. Lee, S. Cho, S. Shin, M. Kim, C. Song, K. Min. SAE Technical Paper 2021, 11.

4. I. Park, H. Choi, K. Min. KSAE Autumn Conference and Exhibition 2023.

5. J. SIM, M. Kang, M. Min, E. Lee, J-Y. Jyoung. Renewable Energy 2022, 190, 959-970.

6. J. SIM, M. Kang, M. Min. Journal of power sources 2022, 544, 231912.

7. J. SIM, M. Kang, M. Min, International Journal of Hydrogen Energy 2021, 46, 27731-27748.

8. J. Cho, H. Oh, J. Park, K. Min. International Journal of Hydrogen Energy 2014, 39, 459-468.

9. J. Cho, H. Oh, J. Park, K. Min. International Journal of Hydrogen Energy 2014, 39, 495-504.

10. J. Park, H. Oh, J. Cho, K. Min. The Korean Hydrogen & New Energy Society Conference 2013, 24, 216-222.

11. H. Oh, Y-I. Lee, G. Lee, K. Min. Journal of Power Sources 2017, 345, 67-77

12. M. Kang, J. Sim, K. Min. International Journal of Hydrogen Energy 2022, 47, 29467-29480.